UV

UV is the most popular way to give special effect to a paper surface. Simply speaking, UV is put a shiny oil onto the paper to make it lightening and protect it’s surface, it is tough, anti-corrosion, anti-rub and anti-crack, and this layer of oil can be made into colorful picture as well, that make the package look amazing.

Offset Printing

Offset Printing is by means of rubber blanket transfer the picture and text to the target surface. Rubber blanket can be fit for an irregular surface and transfer fully printing ink onto it. Offset printing is the most often printing technology presently, it use widely on book, newspaper, paper package product surface.

Thread Forming

The principle of thread forming is similar to the one of embossing. It uses a pair of dies to make plastic deformation on the prints by giving a certain level of pressure. It results in different levels of depth in the image and texture expression, and makes the prints more three-dimensional and artistically appealing.

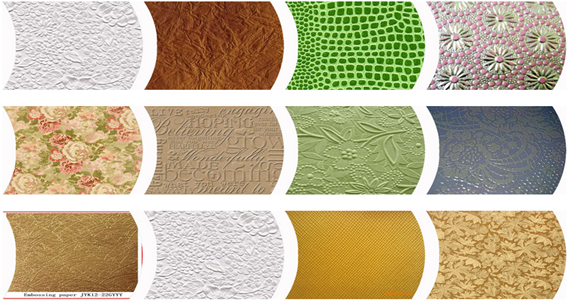

Embosing

Embossing is a kind of special technique used for ornament and processing on prints. It requires the use of a pair of dies engraved with desired image or text, one to be raised and the other to be recessed. By putting the printing material between the dies, applying a certain level of pressure on the dies, it results in an embossed impression, which will improve the prints by providing a three-dimensional effect,a level of depth, and adding the finishing of touch. It is often used in the decoration of trademark printing, cigarette packaging, paper box, greeting card, bottle label, etc.

Foil Stamp

The process of foil stamping uses heat to transfer the aluminum layer of the electrochemical aluminum sheet (also known as hot stamping foil) to the surface of the printing material, so as to provide a special metallic effect. Because the material used for foil stamping is electrochemical aluminum, foil stamping is also known as electrochemical aluminum hot stamping. Foil stamping can improve the prints by providing detailed images, bright colors, and high abrasion resistance. It is more effectively used for trademark and registration logo.

Screen Printing

Screen printing is a kind of stencil printing. The process is, forcing and transferring the ink into the openings of the printing plate (paper plate or other substrate) onto the printing surface (paper, porcelain, etc.). The technique of screen printing is easy to manipulate, requiring simple tools, however, giving high flexibility with low cost on printing work. It is used widely in the areas of painting, poster, business card, cover binding, trademark, textile printing and so on.

Pad Printing

Pad printing is a printing process that uses a hemispherical shaped printing pad made of silicone rubber, to press the printing plate and transfer the ink to the heterogeneous surfaces of the substrate (such as instrument, electronic parts, toys, etc.). It is suitable for the use on plastic, toys, glass, metal, porcelain, electronics, IC encapsulation, etc.

Electroplating

Electroplating is, by the principle of electrolysis, a process that coats some metal surfaces with a thin layer of other kind of metal or alloy. The electrolytic action results in the surfaces of metal or other kind of material coated with a layer of metal film, so as to prevent metal oxidation (for example, rustiness), to improve abrasion ability, conductibility, reflection, corrosion protection (eg. copper sulfate), and aesthetic qualities, etc.

Paint spraying

This technique is mainly used on wooden boxes. Spraying different colors of paint on plain wooden boxes, and then applying the screen printing or foil stamping technique, can make the fonts or images more detailed and color saturated.